Introduce the quality control process of 3C product mold production

The quality control process of 3C product mold production covers multiple links from design to after-sales service. The following is a specific introduction:

Quality control during the design phase

Design review: Organize cross departmental teams, including design engineers, process engineers, production personnel, etc., to review the design scheme of 3C product molds. Check whether the design meets the requirements of product functionality, accuracy, appearance, etc., and evaluate the structural rationality, manufacturability, and maintainability of the mold.

DFM analysis: Using Design Manufacturing Integration (DFM) technology to analyze mold design. Predict possible problems in the manufacturing and molding process of molds through simulation software, such as uneven plastic flow, stress concentration, and difficulty in demolding, and optimize the design in a timely manner.

Quality control of raw material procurement

Supplier selection: Establish a list of qualified suppliers and select raw material suppliers with good reputation and quality assurance. Conduct on-site inspections of suppliers to evaluate their production capacity, quality control system, and after-sales service capabilities.

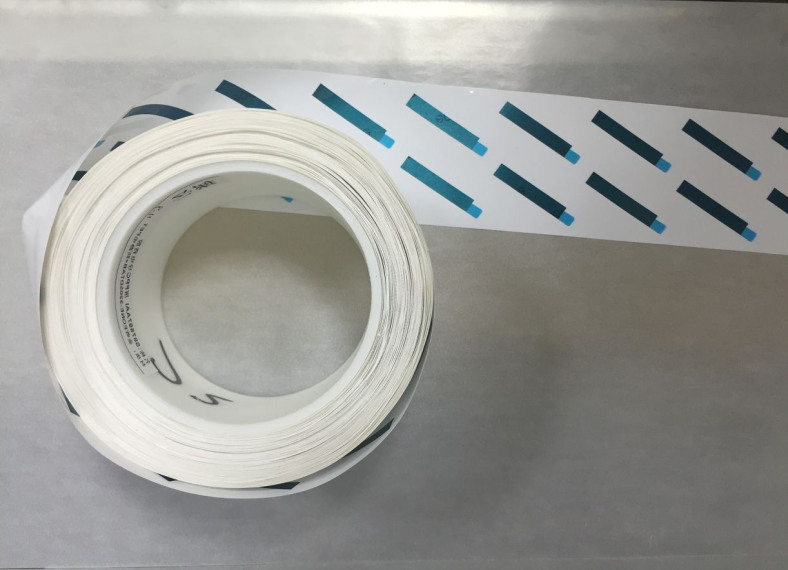

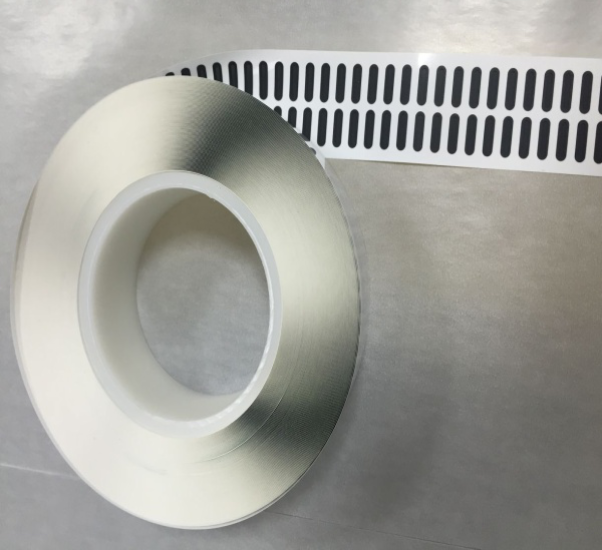

Material inspection: After the arrival of raw materials, strict inspection shall be carried out in accordance with relevant standards and technical requirements. Check whether the specifications, models, hardness, and organizational structure of the materials meet the requirements, and require the supplier to provide material certification and inspection reports. For key materials, sampling testing can be conducted, such as spectral analysis, metallographic examination, etc., to ensure the stability of material quality.

Process quality control

First article inspection: At the beginning of each processing step, the first product is inspected comprehensively. Check whether the dimensional accuracy, surface quality, geometric tolerances, etc. meet the requirements of the drawings, and only proceed with batch processing after confirming that they are correct.

Process inspection: Quality control personnel regularly inspect the machining process, checking the operation status of equipment, tool wear, and the execution of process parameters. Timely detect and correct deviations and violations during the processing to prevent the occurrence of batch quality problems.

Finished product inspection: After the mold processing is completed, a comprehensive finished product inspection is carried out. Use precision measuring equipment such as coordinate measuring instruments and projectors to measure the key dimensions of the mold, ensuring that the dimensional accuracy is controlled within the tolerance range required by the design. At the same time, check the surface quality of the mold, including roughness, scratches, cracks, and other defects.

Assembly and commissioning quality control

Assembly inspection: During the mold assembly process, strictly follow the assembly process specifications for operation. Check whether the assembly sequence, fit clearance, and connection tightness of the parts meet the requirements. Measure and adjust key assembly dimensions to ensure the assembly accuracy of the mold.

Debugging and optimization: After the mold assembly is completed, debug it to observe whether the mold operates smoothly in opening, closing, ejecting, cooling, and other actions, and whether there is any interference between the components. Through trial molding, quality inspection is carried out on the formed products, such as appearance, dimensional accuracy, performance, etc. Adjust and optimize the mold based on the trial results until the product quality meets the design requirements.

After sales quality control

Regular Follow up: After the mold is delivered for use, regular follow-up visits are conducted with customers to understand the usage and product quality of the mold. Collect customer feedback on issues and opinions, and provide timely technical support and solutions.

Maintenance management: Establish a comprehensive maintenance management system to strictly control the maintenance process of molds. Before repairing, maintenance personnel need to analyze the cause of mold failure and develop a reasonable repair plan. After repair, inspect and test the repair area to ensure that the repair quality meets the requirements. At the same time, record relevant information during the maintenance process, such as maintenance time, maintenance content, replaced parts, etc., in order to track and record the maintenance status of the mold.

Please first Loginlater ~