3C product mold production

The production of 3C product molds is a complex and intricate process, covering multiple stages from product design to mold manufacturing, debugging, and ultimately mass production. Here is a detailed introduction:

Product Design and Mold Planning

Product design: Based on market demand and customer requirements, design the appearance, structure, and functionality of 3C products. In the design process, full consideration should be given to the manufacturability of the product, assembly process, and feasibility of mold design to ensure that the product can be smoothly produced through mold production.

Mold planning: Determine the type, structural form, and manufacturing process of the mold based on the structural characteristics and production batch of the product. For example, for small plastic shells, injection molds may be used; For metal shells, stamping molds or die-casting molds may be used. At the same time, it is necessary to plan key elements such as the number of mold cavities, parting surfaces, and demolding methods to improve production efficiency and product quality.

mould design

Generate 2D drawings: Based on the 3D model of the product, use professional mold design software to design 2D drawings of the mold, detailing the technical requirements such as dimensions, tolerances, and surface roughness of each part.

Analysis and Optimization: Simulate and analyze mold design, such as injection molding analysis, stamping analysis, etc., predict possible problems such as uneven plastic flow, part deformation, etc., and optimize the design to reduce the number of mold trials and improve mold quality.

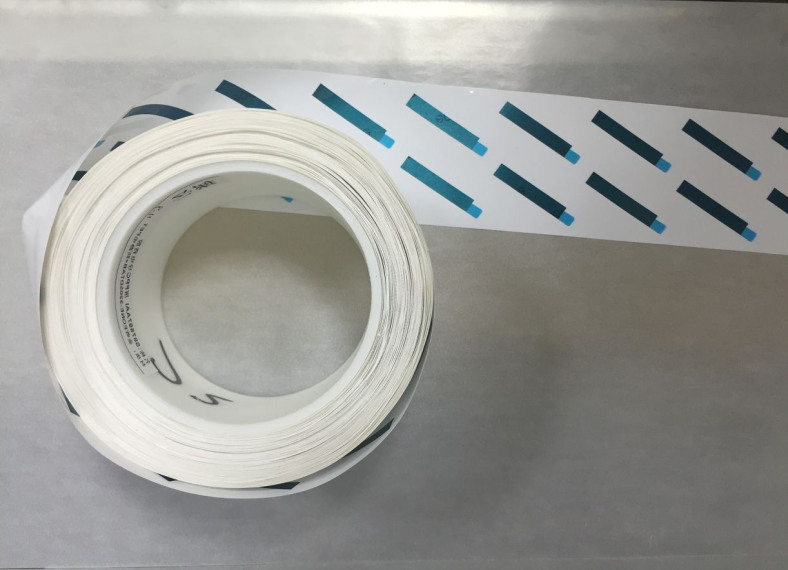

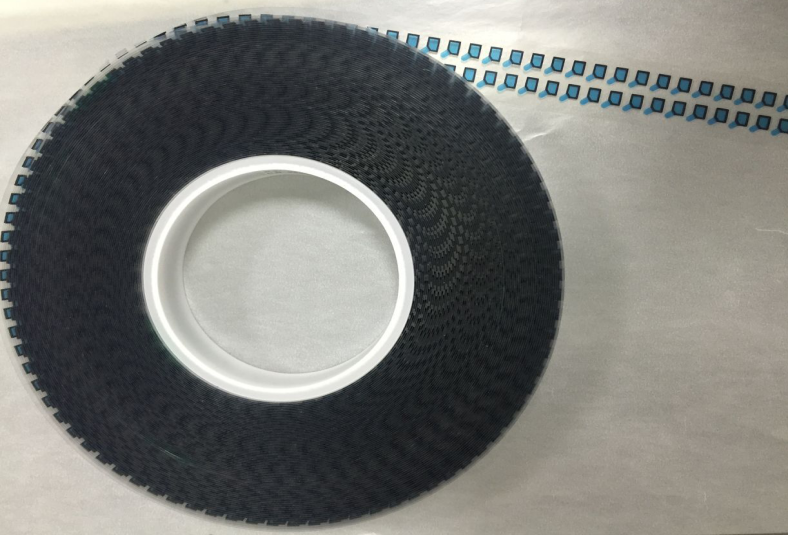

Mold manufacturing

Part processing: According to the mold design drawings, various processing equipment and processes are used to process the various parts of the mold. Common processing methods include CNC milling, electrical discharge machining, wire cutting machining, grinding machining, etc. During the processing, it is necessary to strictly control the dimensional accuracy and surface quality of the parts to ensure that they meet the design requirements.

Mold assembly: After cleaning and deburring the processed mold parts, assemble them according to the assembly drawing. During the assembly process, attention should be paid to the installation sequence of parts, clearance between fittings, and connection and fastening methods to ensure the assembly accuracy and stability of the mold. At the same time, install the guiding mechanism, demolding mechanism, cooling system and other auxiliary devices of the mold to ensure its normal operation.

Mold debugging and optimization

Trial mold: After the mold manufacturing is completed, the first step is to conduct a trial mold. Install the mold on the corresponding molding equipment, such as injection molding machines, stamping machines, etc., for the first trial production. During the trial molding process, it is necessary to record the molding process parameters, such as injection pressure, temperature, holding time, stamping speed, stamping pressure, etc., and observe the molding situation of the product, such as appearance quality, dimensional accuracy, demolding situation, etc.

Adjustment and optimization: Adjust and optimize the mold based on the trial results. Such as adjusting molding process parameters, repairing surface defects of molds, optimizing cooling systems, etc., to improve product quality. Sometimes it may be necessary to make partial modifications or adjustments to the mold, such as modifying the cavity size, adjusting the demolding mechanism, etc., until the product meets the design requirements.

Mass production and maintenance

Mass production: After the mold is debugged and optimized, it enters the mass production stage. In the mass production process, it is necessary to strictly follow the established molding process and production flow for production, regularly maintain and upkeep the molds, ensure the stability of the mold performance, and guarantee the consistency and stability of product quality.

Maintenance: Regularly clean, lubricate, inspect, and repair molds to promptly identify and address any issues that may arise during use, such as wear, deformation, cracks, etc. At the same time, establish a maintenance file for the mold, record the maintenance history and related information of the mold, and provide reference for the subsequent maintenance and management of the mold.

Please first Loginlater ~